01.

Enhanced Thermal Insulation

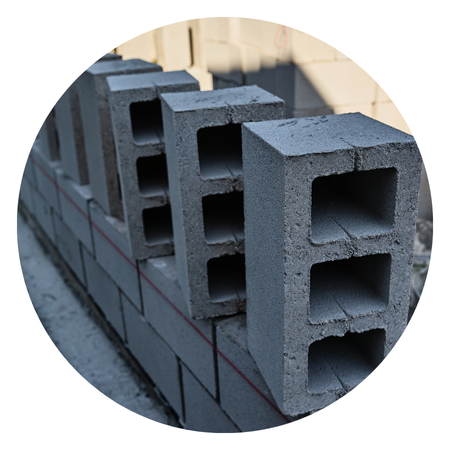

Gazebo Blocks provide superior thermal insulation, resulting in better temperature regulation and lower energy costs for heating and cooling.

02.

Cost Efficient

Gazebo Blocks are designed to be cost-efficient, offering excellent value through reduced construction time and lower overall costs compared to traditional AAC blocks.

03.

Increased Strength and Durability

Engineered for higher compressive strength and durability, Gazebo Blocks are more resistant to stress and environmental factors, ensuring longer-lasting structures.

04.

Eco-Friendly Manufacturing

For our customers we offer a complete «key ready» project implementation.